Turnkey can making systems

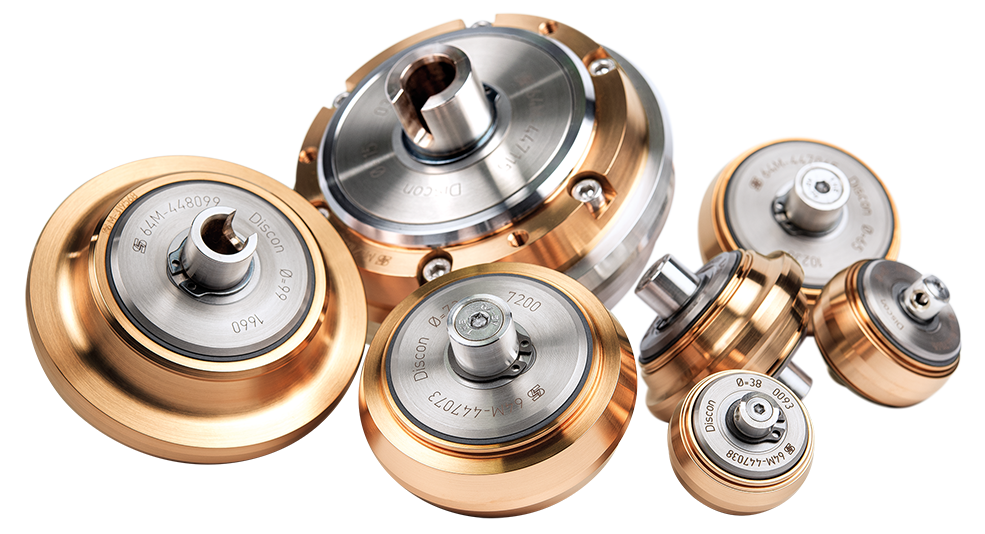

We provide a complete range of machines and components for the can making industry focusing on three-piece and two-piece can production lines and end making systems. Our machines cover the entire manufacturing process. Today, with more than 15,000 machines and system components installed, our production systems can be found virtually all over the world.

Our products

We design, manufacture, install and maintain fully integrated canbody production lines, operating from very low speeds to a maximum of 1,200 cans per minute, to produce cans, pails, drums and irregularly shaped metal containers. The range of machines contains slitters, transfer systems, welding machines, seam protection and curing systems, bodyformers and seamers, two-piece can production lines, endmaking and peel-off systems.

Products

News

-

BPC, SPC powder (coating) systems

Production of unit has been stopped because key components are no longer available. As many electronic components used in older Frei AG systems are getting phased-out by suppliers, the need to adapt electrical systems to accommodate new equivalent replacements is …

-

PCA, PCB and ECM, FCM gas curing systems

Production of unit has been stopped because key components are no longer available. As many electronic components used in older Frei AG systems are getting phased-out by suppliers, the need to adapt electrical systems to accommodate new equivalent replacements is …

-

mySoudronic – Our brand-new customer portal!

We provide support for you and your operators anytime, anywhere, and on any device with mySoudronic. This single point of entry offers a wide range of useful applications. Train your operators with Academy e-learning modules or help yourself with self-support …

Events

Our services

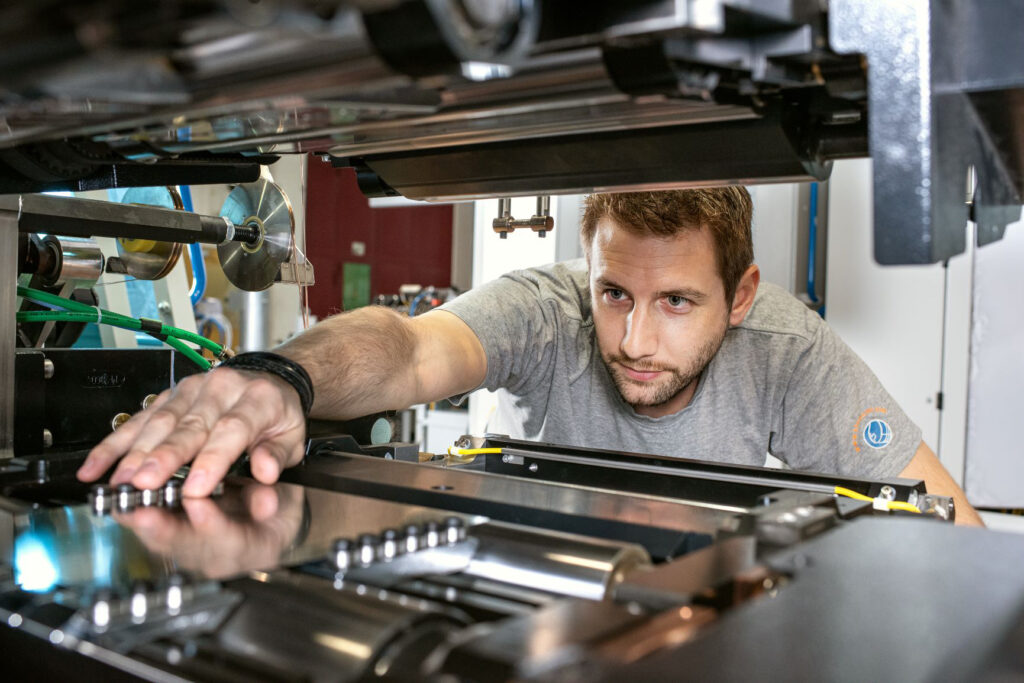

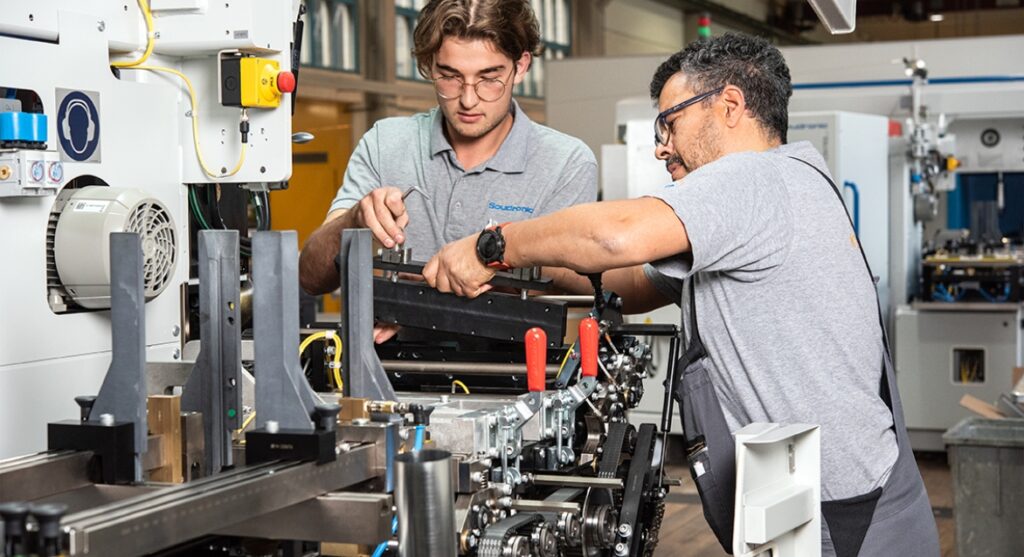

Customers learn the meaning of Soudronic support long before they sign a contract. We listen to their needs, suggest solutions, and accompany them throughout the entire decision-making process. Our service starts with the delivery of the machine or system and continues for the entire duration of its productive life. We make sure that our customers’ systems run smoothly by providing training programs for operating personnel and support through our skilled technicians. We provide a comprehensive inventory of 30,000 genuine spare parts and standardized solutions for upgrades and conversions.

Services

Explore our World of Factories

Dive into our 3D-world showcasing complete can production lines. Explore our high-speed performance or flexible three-piece can making lines. Move through the buildings to discover end making or two-piece can making systems. Learn more about our great upgrades and conversions offers that will ensure the productivity of your valuable installations.

Soudronic Group

Founded in 1953, Soudronic’s headquarters are located in Bergdietikon near Zurich. Today, the company employs a total of around 600 people in its development and production facilities throughout the world and all subsidiaries. The company’s sales and service network covers more than 120 countries, servicing a large and globally spread customer base. Thanks to its sound financial basis, Soudronic remained independent throughout its 70 years of history.

Our brands and subsidiaries

Members of Soudronic Group are Sabatier in France, who are specialized in general lines and Ocsam Cepak in Italy, specialized in slitters and transfer systems. In 2020 welder specialist Can Man from Switzerland joined Soudronic Group as well as Frei AG, Switzerland, as additional brand for coating and curing systems.

Soudronic and sustainability

At Soudronic, we believe the canmaking industry has a responsibility to enlighten consumers about the largely unperceived ecological benefits of our products. If this helps to change consumer perceptions about metal packaging – and push up recycling rates still further, we will already have taken a major step forward.

Career@Soudronic

Soudronic Group counts around 600 employees in eleven countries and offers motivated and well-qualified individuals of all ages challenging job and career opportunities in various areas like engineering, assembly, manufacturing, maintenance, administration, sales or customer service.