Three-piece can manufacturing

Typically, a production system for three-piece cans consists of six separate stations; a slitter to cut the tinplate base material into body blanks of the required size; a transfer system to feed the cut blanks from the slitter to the canbody welder; a welding unit to shape and weld the canbody; a seam protection system to prevent oxidation and chemical reactions damaging the welded can; a curing system to dry and harden the coating; and a bodyformer to give the canbody its final profile and shape. A single control system, equipped with a touchscreen panel, permits central operation and control of the entire production line.

Products overview

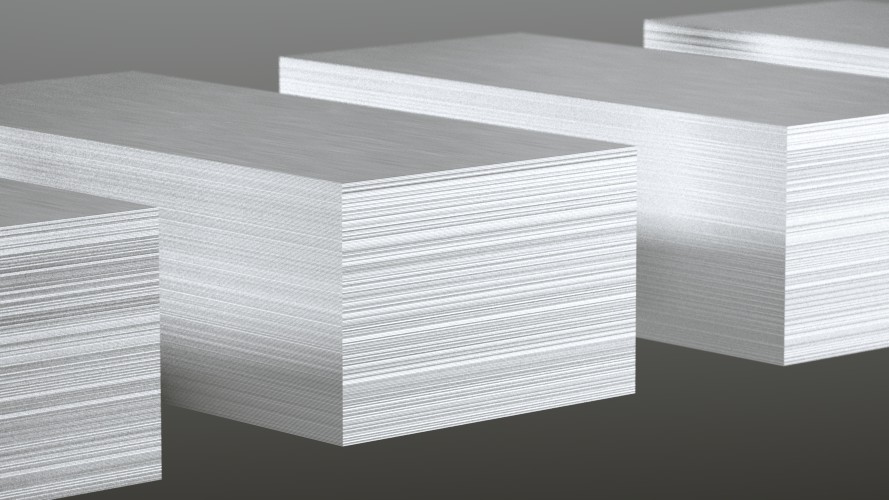

Slitter

High precision guillotine slitters or rotary slitters with fully automated cutting heads that allow fast format changes.

Transfer Systems

High-capacity transfer systems for all system layouts and configurations with a feeding capacity of up to 1,500 blanks per minute.

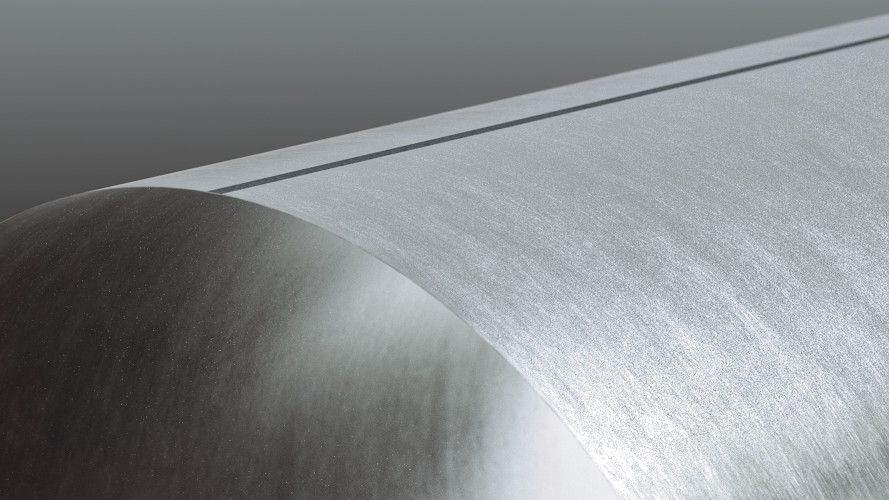

Canbody Welder

Welding machines that offer maximum speed, efficiency and flexibility, reliability and user-friendliness.

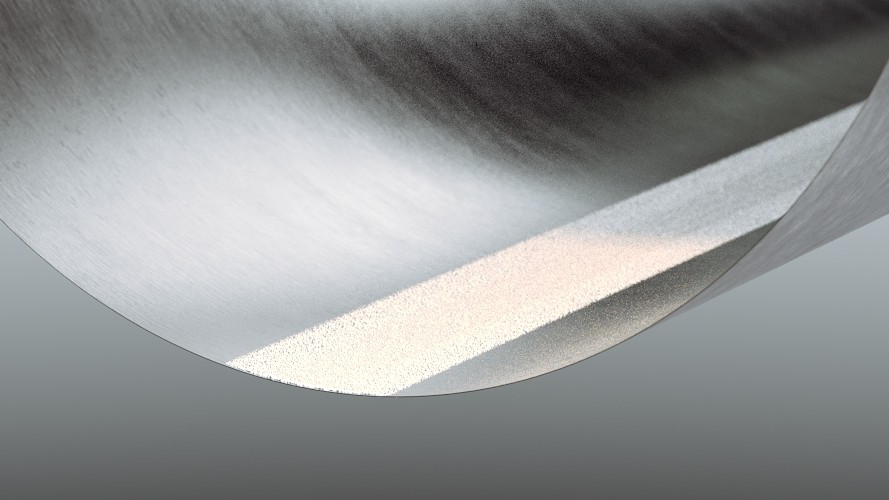

Coating

Fully automated powder-coating or wet-lacquering systems for inner and outer seams at various positions. They guarantee easy, clean operation and low powder or lacquer consumption.

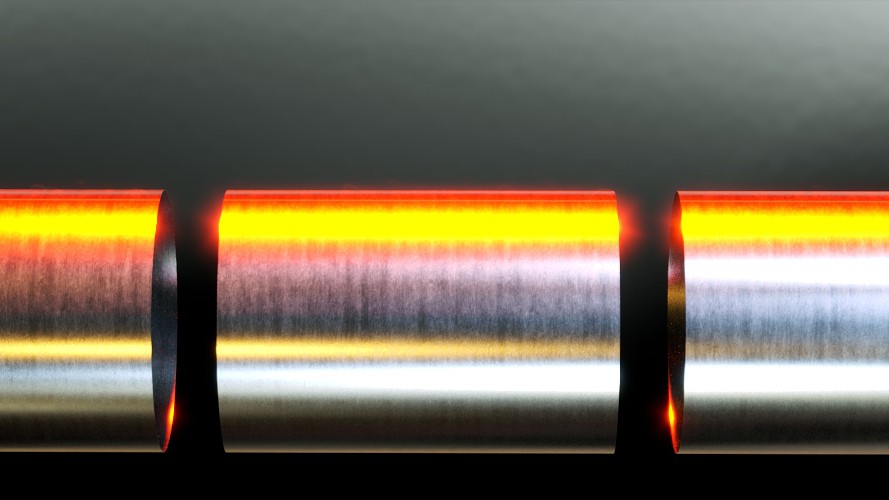

Curing

Modular range of curing systems designed to cure the seam protection layer effectively. Available as gas or induction heating in linear or U-shape.

Can Assembling

Multi-function systems that perform several operations from forming to seaming at low, medium and high speeds. They feature high-level modularity and process capability.

Tester

Pressure decay and light testers for all sizes and shapes i. e. round, square, irregular, cans, drums, pails. Carousel or linear test units adjust easily to the size and shape of the metal container.

2-Piece Cans

Complete production lines for deep-drawn round, conical, rectangular, or irregularly shaped canbodies. High performance presses and 2PC combination machines.

End Making

High efficiency multi-die presses for ends and shells.

Peel-off Ends

Single and multi-lane heat-sealing systems to produce POE.

Conveyor

Conveying systems from trusted third-party suppliers engineered to our customer’s needs.

Palletizer

Customized palletizing systems from trusted third-party suppliers, and stacker for general lines from Sabatier.

Digital Solutions

With Soudronic Digital Solutions, we provide innovative solutions that address your daily challenges.

Accessories

Additional equipment and devices suited for each process step of a can making system.